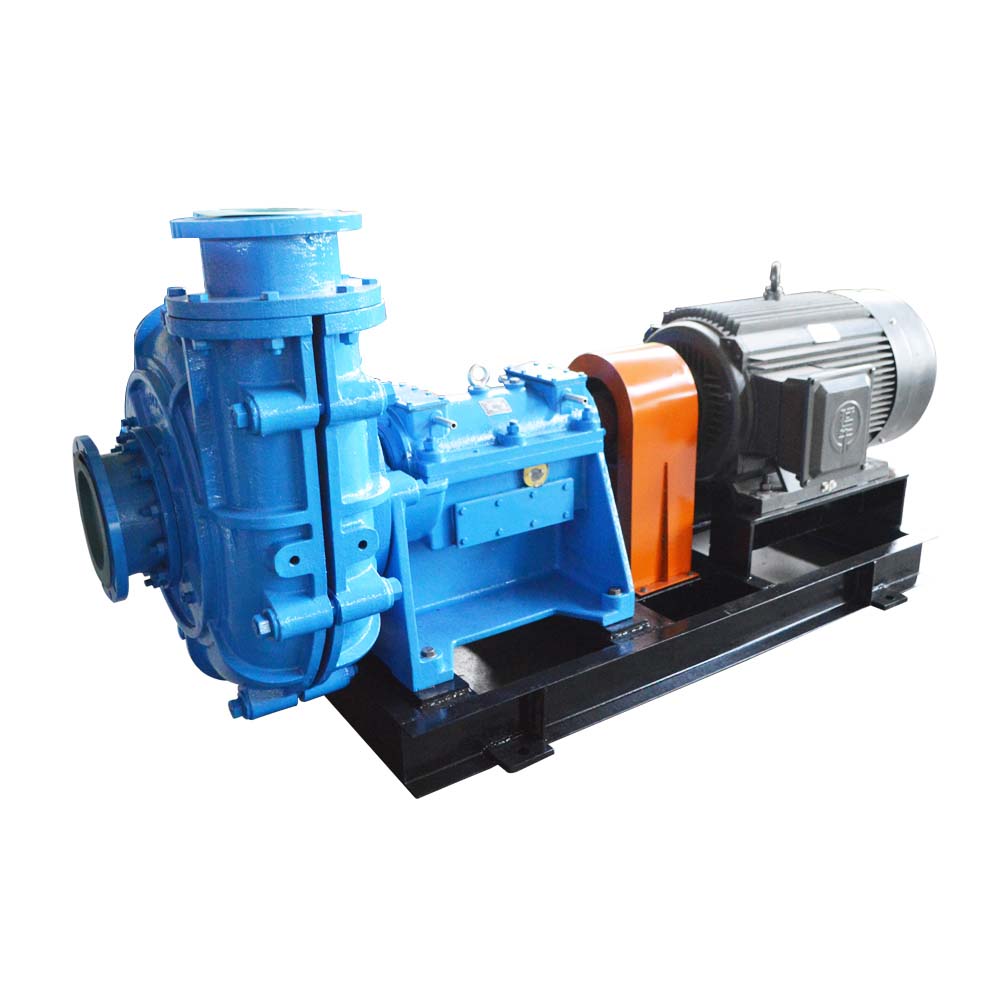

AH Type slurry pump

AH pump is cantilever, horizontal centrifugal slurry pump.Applicable to metallurgy, mining, coal, electric building materials and other industries transport strong corrosion, high concentration slurry.This type of pump can also be used in multi-stage series.The shaft seal of AH pump can be sealed with packing seal or impeller seal. Pump outlet position according to the need 450 intervals, rotating eight different angles to install and use.

Properties

Capacity(Q):3.6-1620m3/h

Head(H):5-92m

Operating temperature:Below 80℃

Construction Design

AH slurry pump has two kinds of structure, high chromium alloy and wear-resistant rubber material, alloy and rubber flow parts can be mixed and used crosswise.

Structure Design with convenient maintenance and long Service Life

Shaft and Bearing Assembly

A large diameter shaft with a short overhang minimizes deflection and vibration. Heavy-duty roller bearings are housed in removable bearing cartridge.

Pump Bese

A minimum mumber of through bolts hold the oumo casing to the frame. A ,means of impeller adjustment is provided in a convenient position below the bearing housing.

Shaft Sleeve

A hardened, heavy-duty corrosion-resistant sleeve with “O” Ring seals at both ends protects the shaft. A slip fit allows the sleeve removed or in-stalled quickly.

Centrifugal shaft seal

A large percentage of duties allow the use of the centrifugal seal which eliminates the need of sealing water.

Gland shaft seal

A packed gland type shaft seal is also available and can be fitted with a low or a full flowflush seal water arrangement.

Impeller

The impeller may be either moulded elastomer or hard metal.Deep side sealing vanes relieve seal pressure and minimize recirculation.Cast-in impeller threads are better suited for slurries.

Outer Casing

Split outer casing halves of cast or ductile iron contain the wear liners and provide high operation pressure capacities.

Designed and built for long life with low maintenance

Type AH slurry pump adopt many kinds of sealing systems :expeller drlive seal,packing seal,mechanical seal and all sorts of special combined seals

Expeller drive seal

Use pressure seal produced by impeller and expeller in series,packing orlip sealing ring for shut down seal

Packing seal

The routine sealing systems are suitable for various conditions and can be used in the corrosion or high temperature conditions such as polytetrafluoroe thylene packing,graphite packing and etc,It also can be used in strong abrasive condition duty with shaft ceramic sleeve of spray weld.

Shaft Seal Module Design

Shaft Seal Module

Mechanical seal

World-advanced sealing technique without sealing leakage,integrating construction,convenient installation & replacement,various consrtuctions suit for all kinds of conditions. High hardness ceramic and alloy are adopted for material of friction parts,Design & matching of mechanical seal & sealing box is suitable for fluid state.lt pos- sesses high abrasive resistance & shadeproof to guarantee that sealing effect can be satisfied by customers in various conditions.This type of Me-chanical seal has already gained national patent.

Advanced grease lubricated bearing assemblies

Advanced bearing are large shaft diameter,cylindrical structure for over loading design,small volume,little installation space. Grease lu-brication is adopted with no leakage,a little maintenance,convenient rotor adjustment,It can be used in serials.

Drive Module Design

Innovative cylindrical bearing assembly using oil lubrication

Large shaft diameter,cylindtical structure for over loading design and metric bearing with oil lubrication. The bearing can be used in serials and has the advantages of small volume,high reliability and ate.

Bearing assembly using oil lubrication with horizontally aplit casing

It has the advantages of large shaft diameter,fine rigidity,short cantilever,no bend & vibration in awful conditions.The metric bearing,which is installed directly in the base with horizontally split casing,adopted oil lubrication and is easy to be removed,checked and adjusted. The bearing has cooing water system which can improve its condition,make it operating under lower temperature so as to increase lifetime greatly.