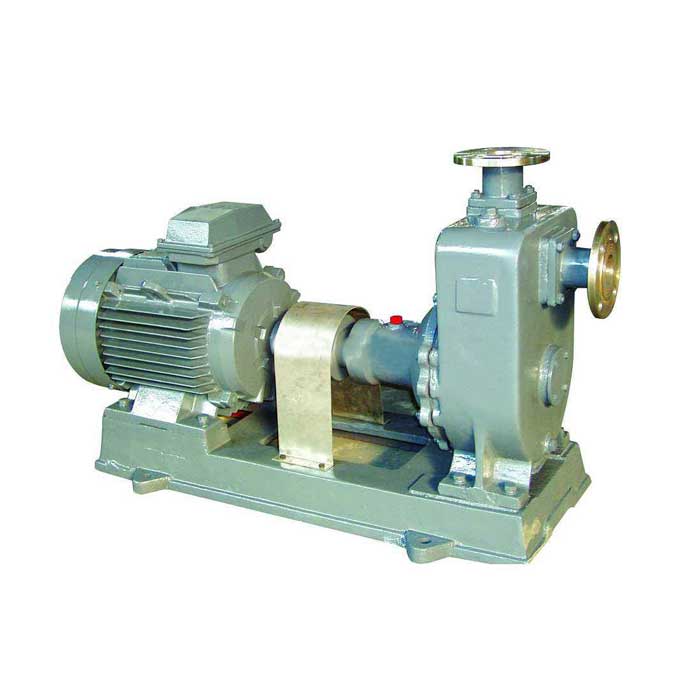

ZX Stainless steel self-priming centrifugal pump

Design features(self-priming centrifugal pump)

The ZX series self-priming pump produced by our company is an energy-saving pump product developed after absorption, digestion and improvement according to relevant technical data at home and abroad. The pump is a self-priming centrifugal pump, which has the advantages of compact structure, convenient operation, stable operation, easy maintenance, high efficiency, long service life and strong self-priming. There is no need to install the bottom valve in the pipeline. It is only necessary to ensure that the pump body has a quantitative drainage liquid before the work, thus simplifying the pipeline system and improving the working conditions.

Work principe

The pump adpots a pump body structure with axial return of liquid. The pump body consists of suction chamber, liquid storage chamber, tubrination chamber, liquid return port, gas-liquid separation chamber, etc.After the pump starts normally, the impeller will suck the liquid in the suction chamber and the air in the inlet line so that the both can mix fully in the impeller.Due to the centrifugal force, the liquid along with the gas flows towards the outer edge of the turbination chamber and then a belt of white foam with a certain thickness and a liquid ring with high-speed rotation come into being on the outer edge of the impeller.The gas-liquid mixture enters the gas-liquid separation chamber through the diffusion tube. Here the lighter gas will be separated from the mixture and rise up and be discharged out of the pump body outlet as the flow speed reduces suddenly.The liquid separated from the gas will return to the liquid storage chamber and enter the impeller again through the return port which mixes again with the gas in the impeller sucked from the inlet line.It then flows towards the outer edge of the impeller due to the high-speed rotation of the impeller. As this process goes round and round, the air in the inlet pipe will reduce constantly until the gas is suctioned out and the self-priming is completed. The the pump will begin to work normally.

For some pumps, a cooling chamber will additionally be mounted on the bottom of bearing body.When the bearing heats and its temperature excess 70℃, the cooling liquid can be injected through any connection of cooling liquid pipe of the cooling chamber for circulating cooling.A front-back seal ring structure is adopted in the pump to prevent the liquid from leaking from high-pressure area to the low-pressure area.The front seal ring is mounted on the pump body while the back seal ring mounted on the bearing body. They should be changed when they are so worn-out that they have an effect on the efficiency and self-priming performance of the pump after the operation for a long time.

Handling liquid

Suitable for clear water, seawater and acid, alkalinity chemical medium liquid and fuel with general fuzziness.

Suitable for urban environment, building, fire control, chemical industry, pharmacy, dyeing, brewing, electric power, electroplating, papermaking, working condition flushing, equipment